1. Product introduction

Sichuan Rongteng automation equipment Co., Ltd. is specialized in the R&D, design and production of natural gas generator. The power of single unit is 250KW, and the combined power can realize 500KW ~ 16MW.

Rongteng’s Gas generator set is widely used in LNG skid mounted liquefaction plant, rig gasification, single power generation (well gas recovery), gas power station and other projects.

Application

● CNG filling station

● Oil and gas field drilling

● Mine exploitation

● Power generation for industry park and residential areas

2. Function introduction

2.1 Unit features

● The gas generator set is suitable for operation in a range of multiple environmental conditions, and its economic performance is better than that of the existing diesel engine; The unit can quickly respond to load changes and deal with more complex conditions.

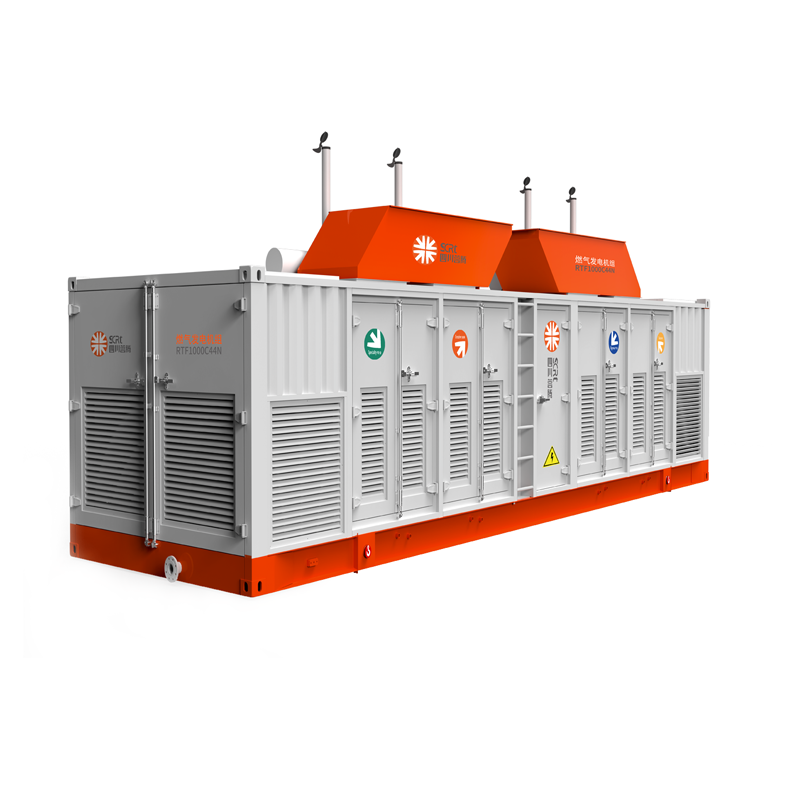

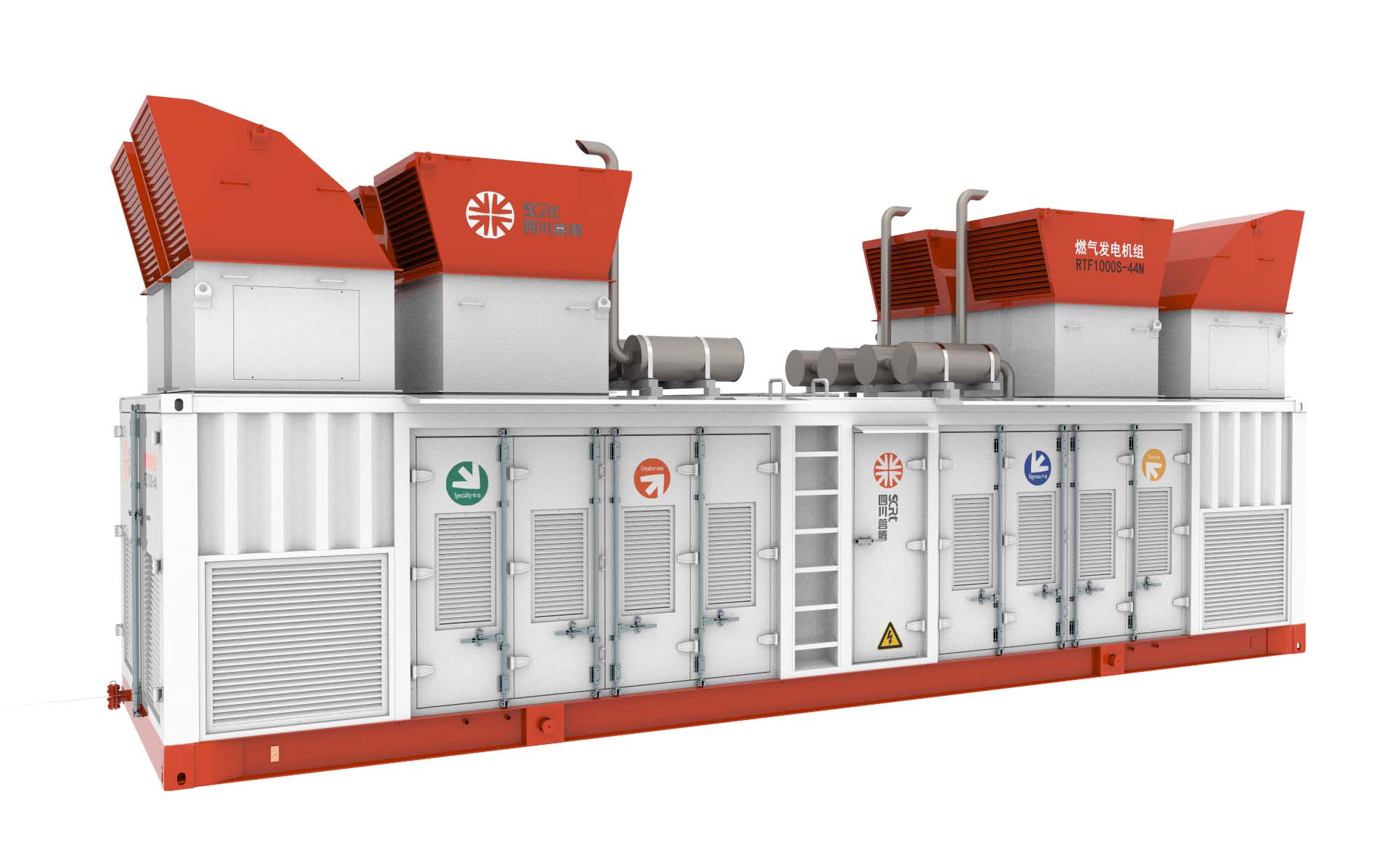

● The gas generator unit adopts the integrated partition box design, the box can meet the operation of multiple environmental conditions, and has the functions of rain proof, sand dust proof, mosquito proof, noise reduction, etc. The box body is designed and produced with special structure and materials of high strength container.

● The shape of gas generator box meets the national transportation standard.

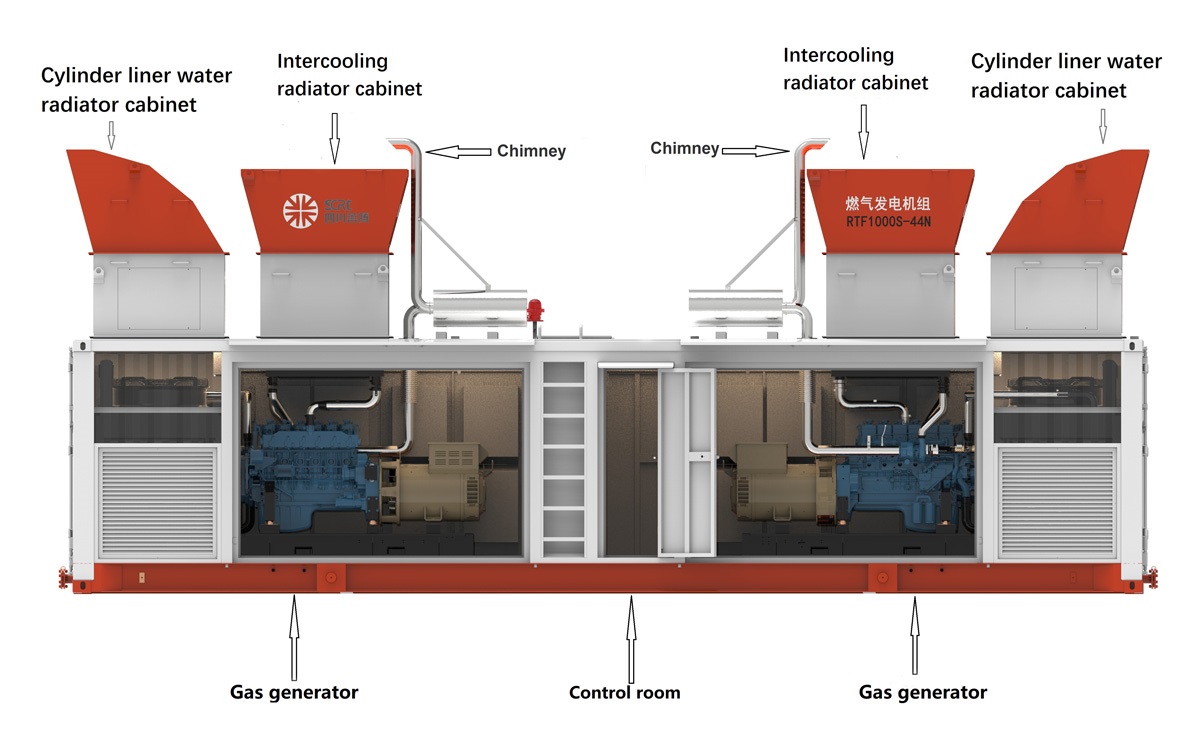

2.2 Unit composition and partition

2.3 Unit cooling

● The cooling system of the gas generator set adopts the fully independent heat dissipation design, that is, the single intercooling heat dissipation system and the cylinder liner heat dissipation system operate independently, so as to meet the unit's single repair and maintenance without affecting the

● operation of other units, which greatly meets the unit's maintenance and practicability.

● The hot air of the cooling system is discharged upward in a unified way to avoid hot air backflow and ensure the normal operation of the cooling system of the unit.

● The cooling system increases the heat dissipation area and heat dissipation under normal heat dissipation conditions, and the cooling effect can better meet the normal operation of the unit under various extreme environmental conditions.

2.4 Power generation efficiency

(Take 250KW as an example for the following data)

● The power of generating set is 250kw/h

● 1kW/h=3.6MJ

● 1Nm³/H natural gas calorific value 36MJ

● 31.25% ≤Power generation efficiency ≤35.71%

● 1Nm³ The natural gas power generation is 3.1-3.5kw/h

2.5 Adaptability of gas medium

| Items | Gas calorific value CV |

Total Sulphur |

Gas Source Pressure |

| Specification | ≥32MJ/m3 | ≤350mg/m3 | ≥3kPa |

| Items | CH4 | H2S | |

| Specification | ≥76% | ≤20mg/m3 | |

| Gas should be treated to be with no liquid, impurity particles 0.005mm, content no more than 0.03g/m3 | |||

| Note: Gas Volume under:101.13kPa.20℃ for standard. | |||

● Applicable gas source pressure range: low pressure (3-15kpa), medium pressure (200-450kpa), high pressure (450-700kpa);

● Suitable gas source temperature range: - 30 ~ 50 ℃;

● Design and calibrate the optimal system scheme and control strategy according to the customer's gas conditions to obtain the optimal gas source economy and equipment stability.

3. Product models

| Geneset Model | Fuel type | Natural gas | Natural gas | Natural gas | Natural gas | Natural gas | |

| Geneset Model | RTF250C-41N | RTF300C-41N | RTF500C-42N | RTF750C-43N | RTF1000C-44N | ||

| Rated power | kw | 250 | 300 | 500 | 750 | 1000 | |

| kVA | 312.5 | 375 | 625 | 937.5 | 1250 | ||

| Reserve power | kw | 275 | 330 | 550 | 825 | 1100 | |

| kVA | 343.75 | 412.5 | 687.5 | 1031.25 | 1375 | ||

| Gas consumption | 3.2NkW/Nm³ | 3.5NkW/Nm³ | 3.2NkW/Nm³ | 3.2NkW/Nm³ | 3.2NkW/Nm³ | ||

| Engine | Engine Model | 1-T12 | MANE 2676 | 2-T12 | 3-T12 | 4-T12 | |

| Number of cylinders * engineering * stroke (mm) | 6-126X155 | 6-126X166 | 6-126X155 | 6-126X155 | 6-126X155 | ||

| Engine displacement (L) | 11.596 | 12.42 | 2*11.596 | 3*11.596 | 4*11.596 | ||

| Starting Method | 24VDC Electric Start | ||||||

| Intake Method | Booster intercooler | ||||||

| Fuel Control | Lean burn, closed loop control | ||||||

| Ignition Control | Electronic control single cylinder independent high energy ignition | ||||||

| Speed control | Electronic speed regulation | ||||||

| Rated Speed | 1500 or 1800 | ||||||

| Cooling Method | Closed-Loop water cooling | ||||||

| Generator | Rated Voltage (V) | 230/400 | 230/400 | 230/400 | 230/400 | 230/400 | |

| Rated Current (A) | 451 | 541.2 | 902 | 1353 | 1804 | ||

| Rated Frequency (Hz) | 50 or 60 | 50 or 60 | 50 or 60 | 50 or 60 | 50 or 60 | ||

| Supply Connection | 3 Phases 4 Lines | ||||||

| Rated Power Factor | 0.8(Delay) | 0.8(Delay) | 0.8(Delay) | 0.8(Delay) | 0.8(Delay) | ||

| Dimension | Net weight (kg) | 3200 | 3600 | 9800 | 15200 | 18600 | |

| (L*W*H) mm | 4200X1500X2450 | 4200X1500X2450 | 6400X3000X3000 | 10600X3000X3000 | 10600X3000X3000 | ||

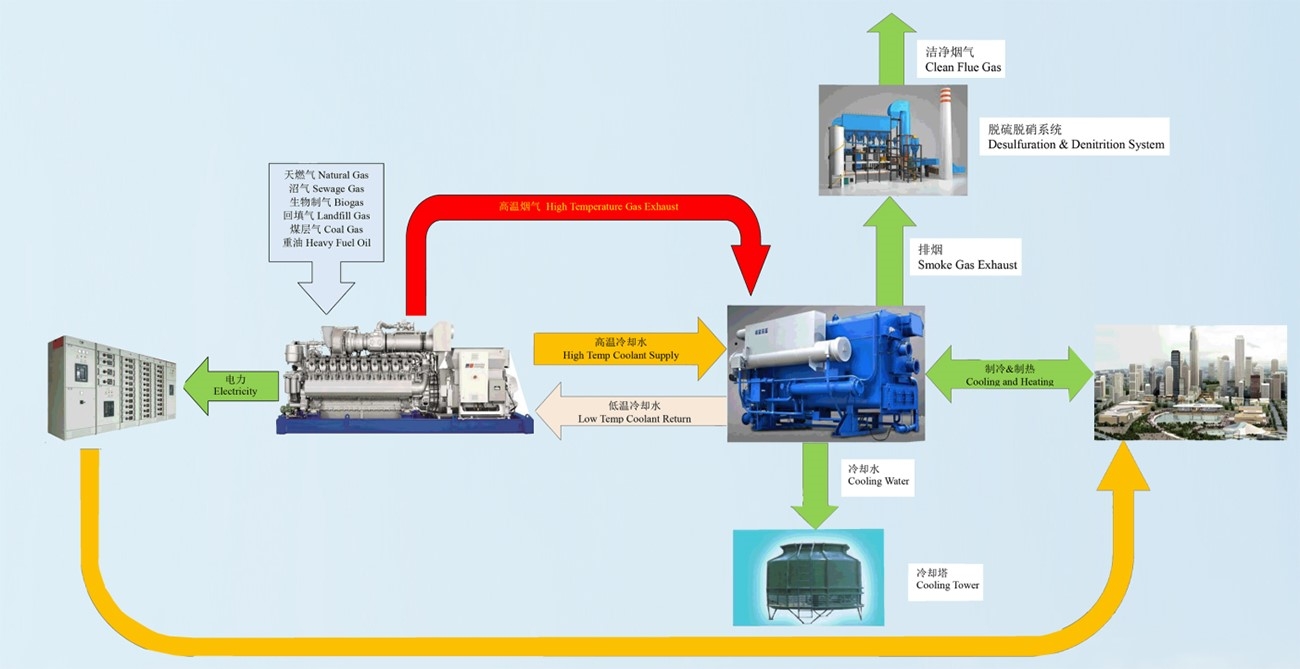

4. Heat recovery

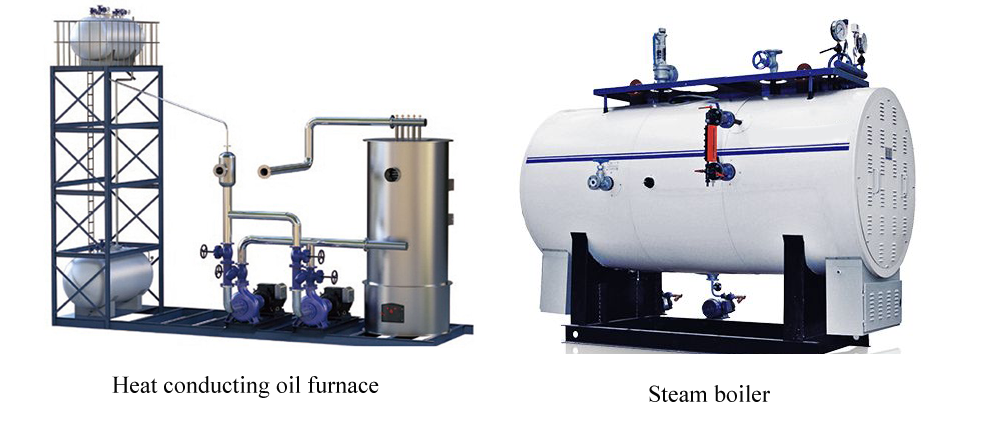

A. Heat recovery of exhaust

The exhaust temperature of our engine is 400 ~ 550 ℃. In the project, it is commonly used in heat supply heat sources such as heat transfer oil furnace, steam boiler and domestic water.

B. Heat recovery of cylinder liner water

The residual heat of cylinder liner water is large. The waste heat recovery not only realizes the cascade utilization of energy in the cogeneration system, but also improves the comprehensive efficiency and economy of the system

-

Wholesale ODM China Cms 200 220 240 260 Carbon ...

-

Factory Directly supply China Diesel Purificati...

-

13 TPD Mini skid mounted LNG Liquefaction plant

-

Customized 2~10×104m3 / D natural gas liquefact...

-

Manufacturing Companies for Outes Brand Zhonggu...

-

Cheap price China Chelate in Regenerative H2s S...