The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Excellent quality Coconut Milk Cream Powder Drying Processing Machine, We warmly welcome domestic and abroad clients send inquiry to us ,we’ve got 24hours performing workforce! Anytime anywhere we have been still here being your partner.

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for China Coconut Processing Machine and Coconut Milk Powder Making Machine, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

Principle

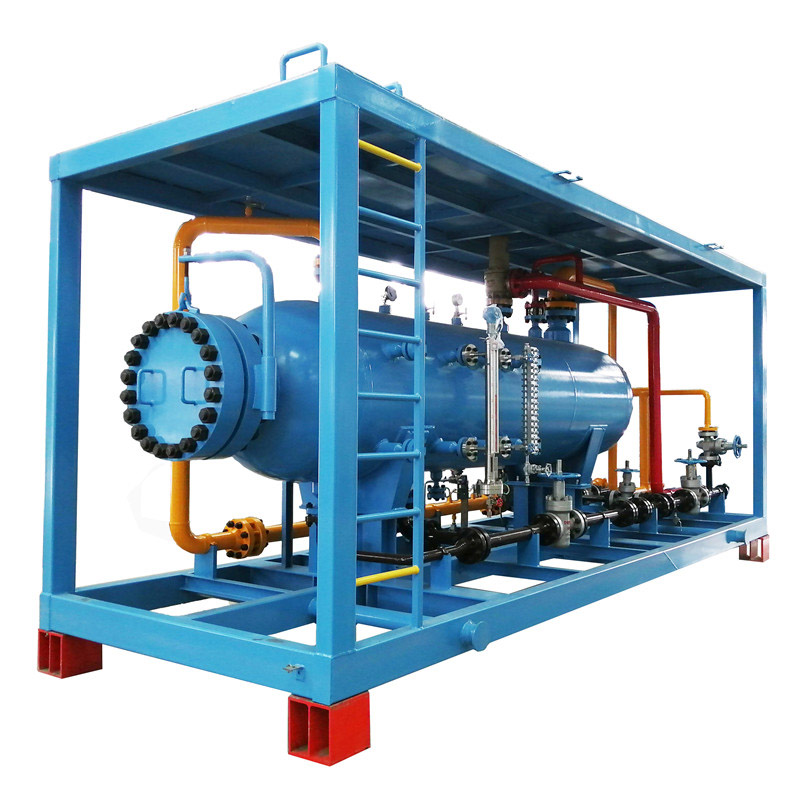

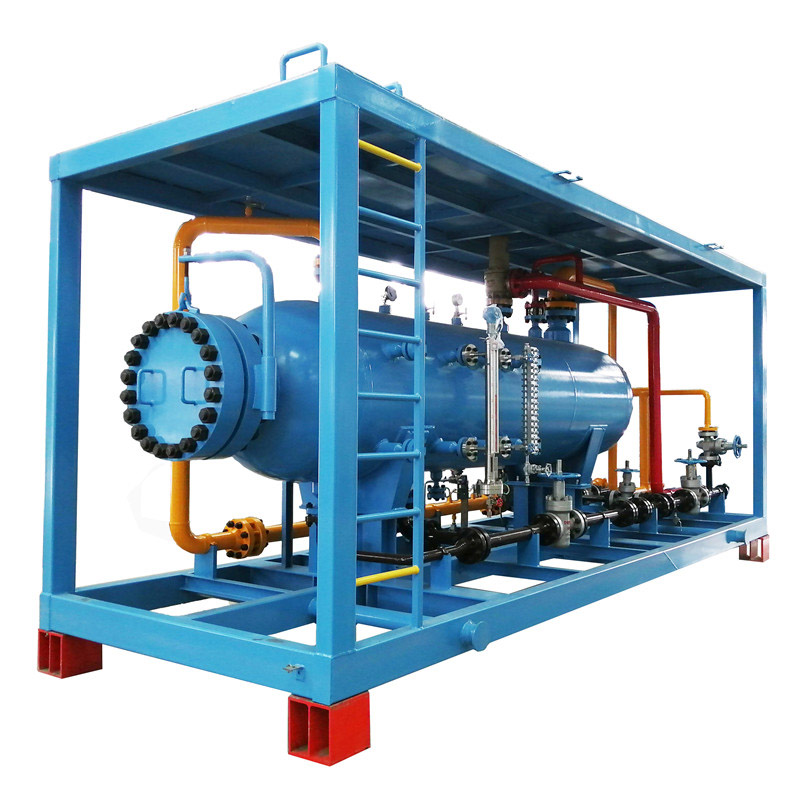

Molecular sieve desulphurization (desulfurization) skid, also called molecular sieve sweeting skid, is a key device in natural gas purifying or natural gas conditioning. Molecular sieve is an alkali metal aluminosilicate crystal with framework structure and uniform microporous structure. When the feed gas containing trace water passes through the molecular sieve bed at room temperature, the trace water and mercaptan are absorbed, thus reducing the water and mercaptan content in the feed gas, realizing the purpose of dehydration and desulfurization. The adsorption process of molecular sieve includes capillary condensation and physical adsorption caused by van der Waals force. From the Kelvin equation, it can be seen that the capillary condensation weakens with the increase of temperature, while the physical adsorption is an exothermic process, and its adsorption weakens with the increase of temperature and increases with the increase of pressure; therefore, the adsorption process of molecular sieve is usually carried out at low temperature and high pressure, while the desorption regeneration is carried out at high temperature and low pressure. Under the action of high temperature, clean and low pressure regeneration gas, the molecular sieve adsorbent releases the adsorbate in the micropore into the regeneration gas flow until the amount of adsorbate in the adsorbent reaches a very low level, and has the ability to absorb water and mercaptan from the feed gas, realizing the regeneration and recycling process of molecular sieve.

Technological process

The process flow of natural gas molecular sieve desulphurization (desulfurization) skid is shown in the diagram. The unit adopts three tower process, one tower adsorption, one tower regeneration and one tower cooling. After removing the entrained hydrocarbon liquid through the feed gas filter separator, the feed gas enters the molecular sieve desulfurization tower. The water and mercaptan in the feed gas are adsorbed by the molecular sieve to realize the dehydration and mercaptan adsorption process. The purified gas from dehydration and mercaptan removal enters the product gas dust filter to remove the molecular sieve dust, and then it is exported as the product gas.

Molecular sieves need to be regenerated after adsorbing a certain amount of water and mercaptan. After filtering the product gas dust, a part of the product gas is extracted as regeneration gas. After the gas is heated to 300 ℃ by the heating furnace, the tower is gradually heated to 272 ℃ through the molecular sieve desulfurization tower which has completed the adsorption process from bottom to top, so that the water and mercaptan adsorbed on the molecular sieve can be separated out and become rich regeneration gas to complete the regeneration process.

Design Parameter

Maximum handling capacity 2200 St.m3/h

System operating pressure 3.5~5.0MPa.g

System design pressure 6.3MPa.g

Adsorption temperature 44.9℃

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Excellent quality Coconut Milk Cream Powder Drying Processing Machine, We warmly welcome domestic and abroad clients send inquiry to us ,we’ve got 24hours performing workforce! Anytime anywhere we have been still here being your partner.

Excellent quality China Coconut Processing Machine and Coconut Milk Powder Making Machine, It is our customers’ satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We offer wholesale prices on all our quality parts so you are guaranteed greater savings.

-

factory Outlets for China CNG Pressure Regulato...

-

2019 New Style China Oil Water Separator for Al...

-

2019 High quality China Triethylene Glycol Dehy...

-

Good Quality China 1mmscfd Skid Mounted Mini LN...

-

20MMSCFD Rongteng modular design NGL recovery ...

-

Fast delivery China Pure Latex Mini Gloves for ...