Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for Factory best selling V37 Kh310 Normal-Temperature Zinc Oxide Fine Desulfurization Chemical Catalyst, ZnO Desulfurizer, We just not only offer the good quality to our clients, but more even important is our greatest support along with the competitive cost.

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for China Fine Desulfurization and ZnO, Upon today, we’ve customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality items with best price. We’re looking forward to doing business with you.

Description

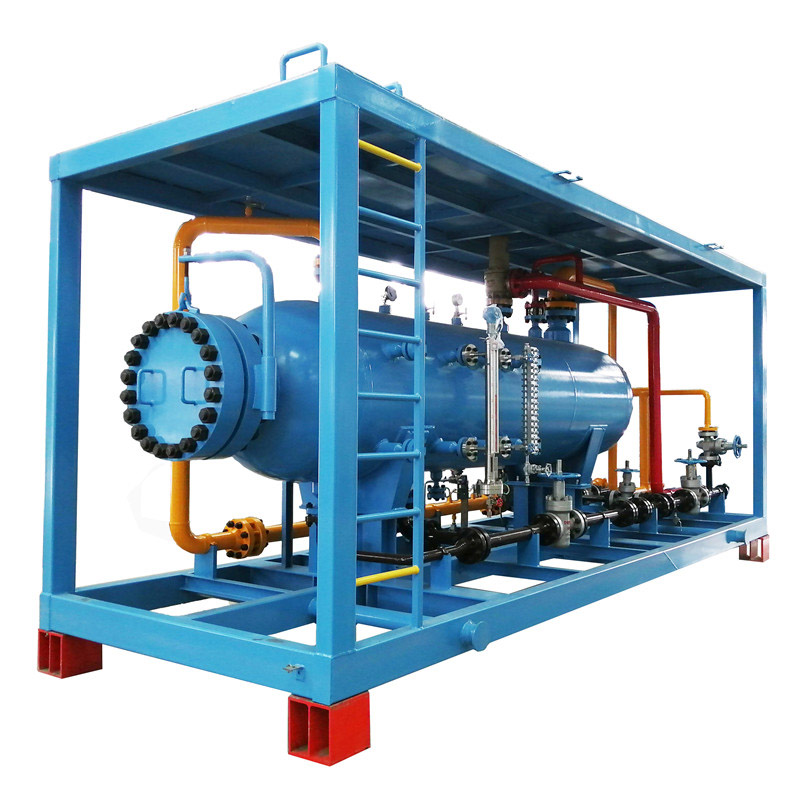

Natural gas decarburization (decarbonization) skid, is a key device in natural gas purifying or treatment.

The content of carbon dioxide in natural gas quality standard should not be more than 3%. And carbon dioxide in the water after the steel has a very strong corrosive. If the pH value is the same, the acidity ratio of carbon dioxide is also higher, so the corrosion degree of carbon dioxide on steel is also higher.

Therefore, for the demand of natural gas decarburization, it is necessary to have a strong thermal effect in the process of decarburization, so the natural gas after humidification heat treatment is not suitable for natural gas decarburization. However, if we do not consider the products of natural gas decarbonization, but adopt the method of low temperature separation, it will directly lead to the efficiency of natural gas decarbonization. At present, the use of natural gas decarbonization treatment can only make alcohol ammonia method.

Flow chart

According to the characteristics of MDEA technology, partial regeneration process is needed for natural gas decarbonization. Among them, the natural gas mainly enters the absorber from the bottom, and contacts with the MDEA solution from the top to the bottom in the absorber, but most of the carbon dioxide solution in the natural gas is decarbonized. The wet purified natural gas is mainly separated by the absorption tower and cooled, and then dehydrated. The MDEA from the bottom of the absorption tower needs energy to enter the dehydration treatment, and the upper part of the absorption tower enters the tower. After decompression, the absorbed carbon dioxide is resolved and heated by steam in the middle of the regeneration tower. Only in this way can the solution temperature be maintained. After the MDEA solution from the bottom of the tower is cooled, the solution enters the top of the absorption, so as to complete the whole circulation process of the solution. In addition, in order to effectively ensure that the solution can be recycled and cleaned again, 15% of the solution is needed for solution removal. In order to maintain the decarbonization process of natural gas, the system will be regenerated through solution.

Functional features

The efficiency of decarbonization by MDEA method is 99%.

In order to remove carbon dioxide (CO2) from feed gas, aqueous solution with alcohol amine as solvent reacts with CO2 in feed gas. Low gas loss and high energy consumption. The alcohol amine method can also be used to remove H2S from the feed gas.

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for Factory best selling V37 Kh310 Normal-Temperature Zinc Oxide Fine Desulfurization Chemical Catalyst, ZnO Desulfurizer, We just not only offer the good quality to our clients, but more even important is our greatest support along with the competitive cost.

Our company has been concentrating on brand strategy. Customers’ pleasure is our greatest advertising. We also source OEM service for Factory best selling V37 Kh310 Normal-Temperature Zinc Oxide Fine Desulfurization Chemical Catalyst, ZnO Desulfurizer, We just not only offer the good quality to our clients, but more even important is our greatest support along with the competitive cost.

Factory best selling China Fine Desulfurization and ZnO, Upon today, we’ve customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality items with best price. We’re looking forward to doing business with you.

-

Good Wholesale Vendors China Mini Gas Central A...

-

7~11 MMSCFD LNG Liquefaction Plant from Chinese...

-

Good quality China CE Approved Biogas Natual Ga...

-

67~134 TPD skid mounted natural gas liquefactio...

-

Wholesale Price China Sulfur Recovery H2s Scrub...

-

2019 New Style China Oil Water Separator for Al...