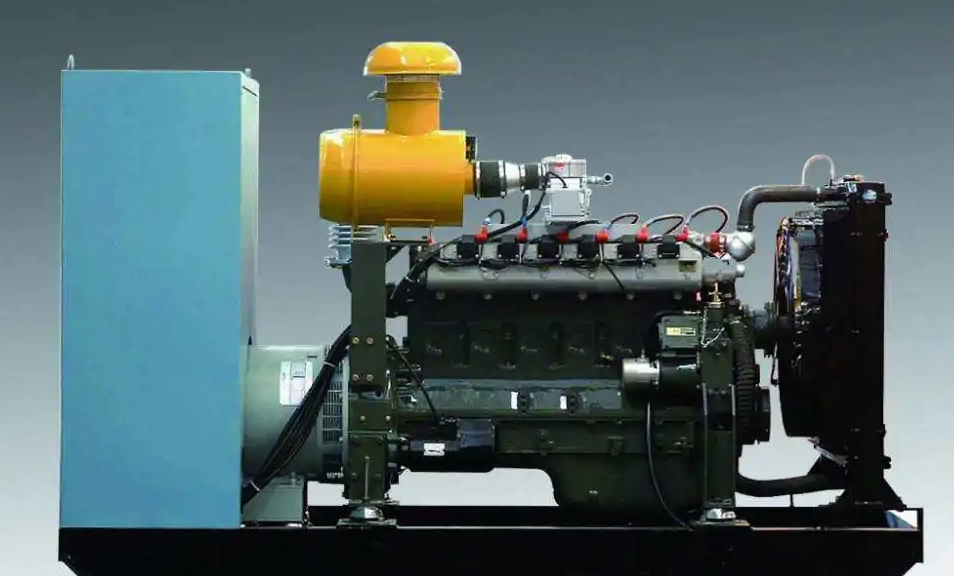

The gas generator set is composed of gas engine, generator, control cabinet and other components. The gas engine and generator are installed on the same steel chassis. The unit uses natural gas, well mouth associated gas, coal mine gas, water gas, refining and chemical tail gas, biogas, coke oven gas, blast furnace gas and other combustible gases as fuel.

It starts quickly and has good economy. Especially due to the demand of high-quality urban life, gas-fired generator units have been widely used in telecommunications, post offices, banks, libraries, hospitals, hotels and other departments as backup power supply. The noise generated by the gas generator set is generally 110 ~ 95 dB under the initial operation condition of the mine. GB 3096-93 environmental noise standard for urban areas has strict provisions on the noise status of urban areas. For class 2 areas (residential, commercial and industrial mixed areas), it is 60 dB (a) in the daytime and 50 dB (a) at night; 55 dB (a) in daytime and 45 dB (a) at night for class 1 area (residential, cultural and educational organ area). The noise generated during the operation of the unit has brought serious noise pollution to the urban environment, affected people’s normal work and life, and limited the wide application of gas-fired generator units. This paper puts forward a set of rectification measures to reduce the noise of gas generator units and promote the popularization and application of gas generator units.

Gas engine noise is the main noise source of gas generator set. Gas engine noise can be divided into aerodynamic noise, combustion noise, mechanical noise, exhaust noise and vibration noise. Aerodynamic noise mainly includes air vibration noise caused by inlet, exhaust and fan rotation, which is directly transmitted to the air. The pressure vibration formed by combustion in the cylinder passes through the cylinder head, and the noise radiated from the body is called combustion noise; The impact of piston on cylinder liner and the impact vibration noise generated by moving parts such as valve train and air injection system are collectively referred to as mechanical noise. When the unit is working, the exhaust gas rushes out of the exhaust valve at high speed, enters the muffler along the exhaust manifold, and finally is discharged into the atmosphere from the tailpipe. Exhaust noise is the largest noise of the engine, which is often about 15 dB (a) higher than that of the engine host, followed by combustion noise, mechanical noise, fan noise and intake noise.

Post time: Mar-04-2022