Here we introduce the technical proposal of natural gas light oil recovery unit and light hydrocarbon recovery unit.

Process equipment of the plant includes: 1 set of compressor skid, 1 set of integrated skid (including feed gas filtration and separation unit, pressure regulating and metering unit, dehydration unit and condensation separation unit), 1 refrigeration unit skid, 2 set of LPG Storage skids, 2 ssets of table light hydrocarbon skids, 2 sets of truck crane pipes, 1 set of instrument air system, 1 set of instrument control system and separation tower skid. Excluding circulating water system, flare and release system, power generation system, power supply and distribution and other public systems.

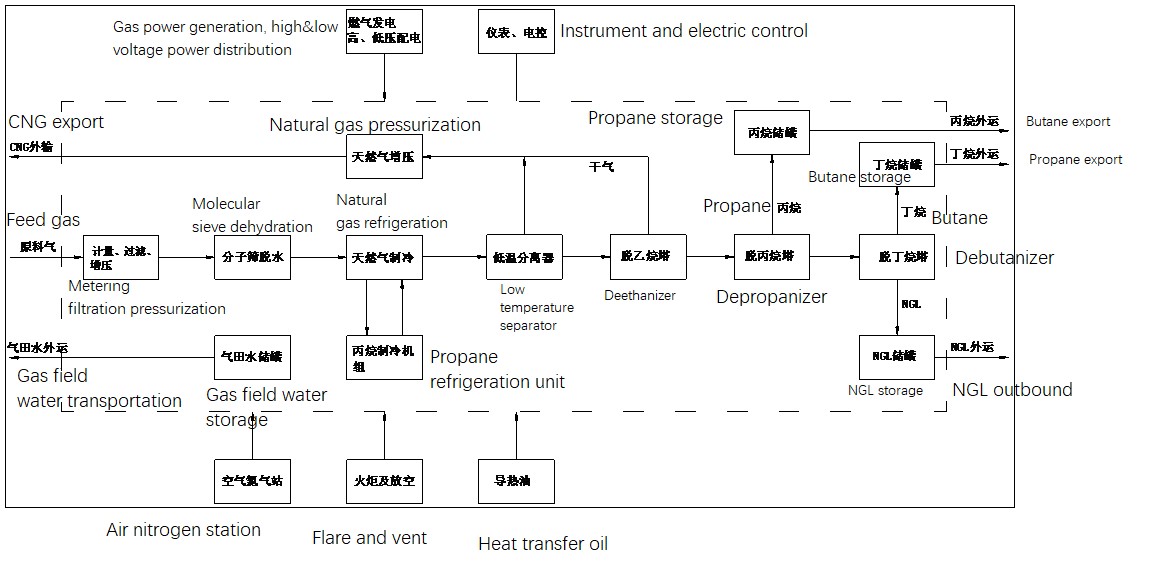

The feed gas enters the inlet separator to filter out mechanical impurities and separate the free water, then enters the compressor after precision filtration by the dust filter, and is cooled to 40 ~ 45 ℃ by the cooler of the compressor itself, and then separates some water and heavy hydrocarbons (in case of excessive heavy components), and then enters the dehydration unit for deep dehydration. The dry feed gas from the dehydration skid enters the condensation separation skid, then it enters the refrigeration unit after precooling to ~ 10 ℃ through the heat exchanger. Next after cooling the feed gas to – 35 ℃ and cooling again through throttling, it enters the low-temperature separator for gas-liquid separation in the light oil recovery unit.

The separated gas phase and liquid phase enter the deethanizer respectively, the tower top gas returns to the heat exchanger for reheating and output outside the boundary, and the tower bottom liquid enters the depropane and debutane tower for separation again. LPG at the top of the tower and stable light hydrocarbon at the bottom of the tower enter the storage tank respectively for loading and export.

The unit is a complete set of equipment. After the set is completed, the stable and efficient operation of the unit must be ensured. The principle of equipment design, manufacturing and finalized product selection is based on domestic, mature technology and advanced performance. If domestic products fail to meet the technical requirements, imported brands shall be selected.

Contact:

Sichuan Rongteng Automation Equipment Co., Ltd.

Phone/WhatsApp/Wechat : +86 177 8117 4421 +86 138 8076 0589

Website: www.rtgastreat.com Email: info@rtgastreat.com

Address:No. 8, Section 2 of Tengfei Road, Shigao Subdistrict,Tianfu New Area, Meishan city, Sichuan China 620564

.

Post time: Dec-17-2023