Description

In the process of natural gas purifying and production, sand often occurs in gas wells. Sand particles flow into the surface gathering and transportation pipeline network with the high-speed flow of natural gas. When the gas flow direction changes, the high-speed movement of sand particles will cause erosion and wear to the equipment, valves, pipelines, etc., especially in the elbow of pipeline, which often leads to wear, puncture and leakage, forming a great safety risk. That is sand removal for natural gas is import.

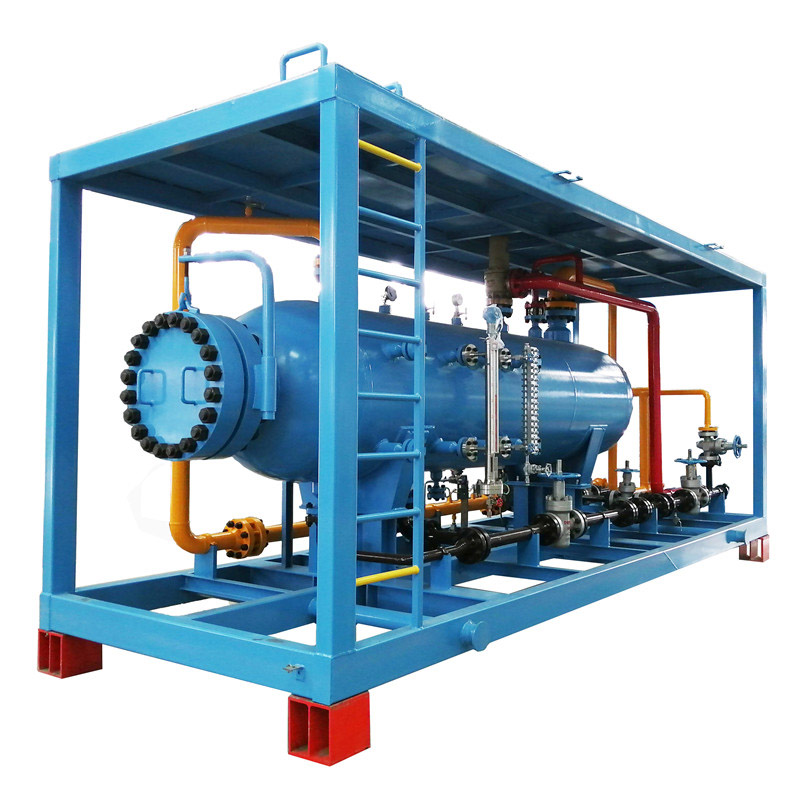

The natural gas desanding skid produced by our company includes desanding tank and sand collecting tank. The desanding tank is connected with the sand collecting tank through stop valve and balance valve respectively. The sand collecting tank is equipped with pressure relief valve, flushing valve and sand discharging valve, and the desanding tank is equipped with air inlet pipe and exhaust pipe. The device can achieve the purpose of sand control, production increase and safe operation.

The Natural gas wellhead sand separator skid is commonly used in natural gas wellhead and test production well field of onshore condensate field, offshore condensate field platform gas wellhead.

The primary purpose of the device is to remove coarse sand from the natural gas produced by the well by means of a cyclone to protect subsequent processing equipment from damage.

Features

1. The natural gas desanding skid is widely applicable to the separation of gas, liquid, gas and solid mixtures.

2. Working accuracy up to 5 microns, and separation efficiency of liquid and solid particles up to 99%.

3. The equipment, instruments, valves and others device are skidded and easy to install and transport. Simple structure, easy operation, safe and reliable use, low maintenance cost.

4. Suitable for all kinds of materials, high temperature, high pressure and corrosive gases.

Technical parameters

| 1 | Capacity | ≤ 300,000m3 / day |

| 2 | Working pressure | ≤32MPa |

| 3 | Sand removal efficiency | 99% |

| 4 | Filtration accuracy | ≤50 micron |