We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Popular Design for Alternative Hydraulic Oil Filter Element Coalescing Filter Oil Water Separator, We can do your customized order to meet your own satisfactory! Our company sets up several departments, including production department, sales department, quality control department and sevice center, etc.

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for China Gas Coalescing Filter and Cleaning Equipment, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

Description

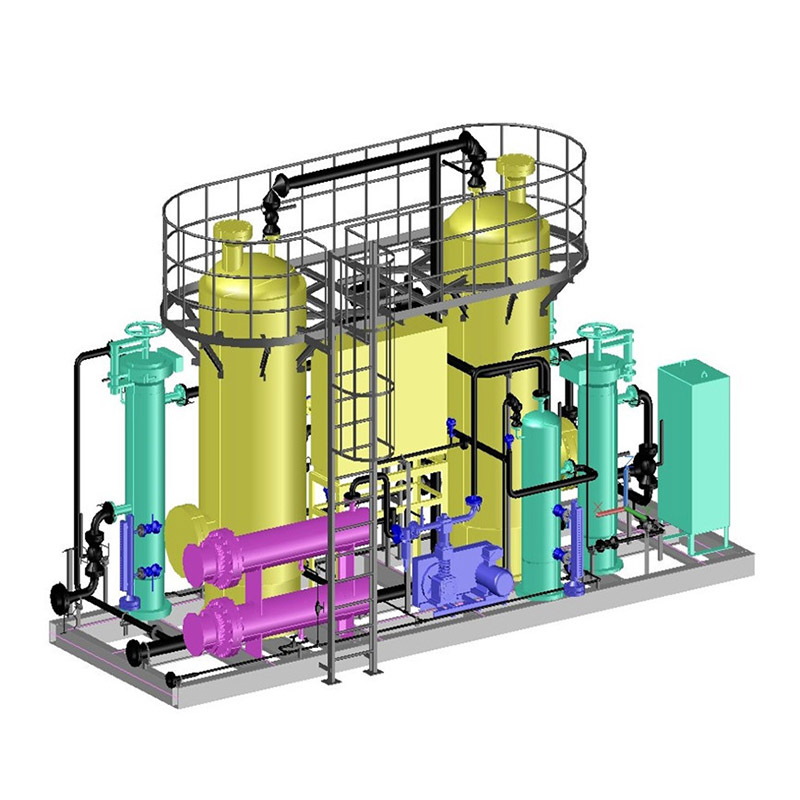

TEG dehydration skid is a key device in natural gas purifying or natural gas treatment. TEG dehydration skid of feed gas is wet natural gas purification, and the unit capacity is 2.5~50×104 . The elasticity of operation is 50-100% and the annual production time is 8000 hours.

The TEG dehydration skid adopts about 99.74% (wt) triethylene glycol (TEG dehydrating agent, removing the most saturated water in wet natural gas purification, purification by TEG absorber after dehydration dry gas (in the factory water dew point pressure condition <-5 ℃) as a commodity to outside gas pipeline.

Flow chart

After water absorption, TEG is regenerated by the method of atmospheric pressure fire tube heating and regeneration. After heat exchange, the heat-depleted liquid is cooled and returned to the TEG absorption tower after pressurization for recycling.

The gas-forming components produced by the regeneration of the rich liquid are mainly water vapor and contain a small amount of hydrocarbons and gases.

In order to eliminate potential safety hazards and avoid direct emissions of environmental pollution, the recycled waste gas from the sulfur recovery device is discharged into the atmosphere after burning in the exhaust gas burning furnace.

Features

1. TEG dehydration process is simple, mature technology, compared with other dehydration method can obtain a larger dew point drop. Good thermal stability. It is easy to regenerate and has the advantages of small loss, low investment and operation cost.

2. A lean/rich liquid heat exchanger is installed before the lean liquid circulating pump, which not only improves the operating conditions of the circulating pump, but also increases the temperature of TEG rich liquid into the triethylene glycol regenerator, effectively recovering part of the heat and reducing the consumption of fuel gas for regeneration.

3. Set a filter on the rich liquid channel to remove the mechanical impurities and degradation products carried in the solution system, keep the solution clean and prevent the solution from foaming, which can reduce the loss of the solvent and is conducive to the long-term stable operation of the device.The direct fire tube heating method adopted in TEG regeneration is mature, reliable and easy to operate.

Technical parameters

|

Inlet gas condition |

||

|

1 |

Flow |

290X104 Nm3/d |

|

2 |

Inlet Pressure |

4.86-6.15 MPa |

|

3 |

Inlet Temperature |

-48.98℃ |

|

Outlet gas condition |

||

|

4 |

Flow |

284.4X104 Nm3/d |

|

5 |

Outlet pressure |

4.7-5.99 MPa |

|

6 |

Outlet temperature |

-50.29℃ |

|

7 |

H2S |

≤20g/m3 |

|

8 |

CO2 |

≤3% |

|

9 |

Water dew point |

<-5℃ |

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Popular Design for Alternative Hydraulic Oil Filter Element Coalescing Filter Oil Water Separator, We can do your customized order to meet your own satisfactory! Our company sets up several departments, including production department, sales department, quality control department and sevice center, etc.

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Popular Design for Alternative Hydraulic Oil Filter Element Coalescing Filter Oil Water Separator, We can do your customized order to meet your own satisfactory! Our company sets up several departments, including production department, sales department, quality control department and sevice center, etc.

Popular Design for China Gas Coalescing Filter and Cleaning Equipment, Excellent quality comes from our adherence to every detail, and customer satisfaction comes from our sincere dedication. Relying on advanced technology and industry reputation of good cooperation, we try our best to provide more quality products and services to our customers, and all of us are willing to strengthen exchanges with domestic and foreign customers and sincere cooperation, to build a better future.

-

Hot Selling for China V32 Kh310 Normal-Temperat...

-

3.5~7 MMSCFD LNG plant and Skid Mounted LNG Plant

-

Custom LPG recovery skid liquefied petroleum ga...

-

Professional Factory for 300ton/Day Gypsum Powd...

-

Factory wholesale China 500kw Remove H2s Biogas...

-

Price Sheet for Quartz Sand Rotary Drying Equip...