Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Professional Factory for 300ton/Day Gypsum Powder Processing Equipment Supplier, Our intention is “blazing new floor, Passing Value”, inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together!

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for China Gypsum Powder Production Line and Gypsum Powder Machine Manufacturer, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

Description

Liquefaction natural gas,shortly called LNG, is condensing natural gas into liquid by cooling the gaseous natural gas under normal pressure to – 162 ℃. Natural gas liquefaction can greatly save storage and transportation space, and has the advantages of large calorific value, high performance, conducive to the balance of urban load regulation, conducive to environmental protection, reducing urban pollution and so on.

Liquefaction is the core of LNG production. At present, the mature natural gas liquefaction processes mainly include cascade liquefaction process, mixed refrigerant liquefaction process and liquefaction process with expander.

Cascade natural gas liquefaction process uses different boiling points of refrigerant under normal pressure to reduce the refrigeration temperature step by step to achieve the purpose of natural gas liquefaction.

Mixed refrigerant cycle (MRC) is a process in which more than five kinds of multi-component mixed refrigerants, such as C1 ~ C5 Hydrocarbons and N2, are used as working fluids to condense, evaporate and expand step by step to obtain refrigeration capacity at different temperature levels, and then gradually cool and liquefy natural gas. Mixed refrigerant liquefaction process is divided into many different types of refrigeration cycle.

The liquefaction process with expander refers to the process of natural gas liquefaction by using high pressure refrigerant to realize reverse Claude cycle refrigeration with adiabatic expansion of turbo expander.

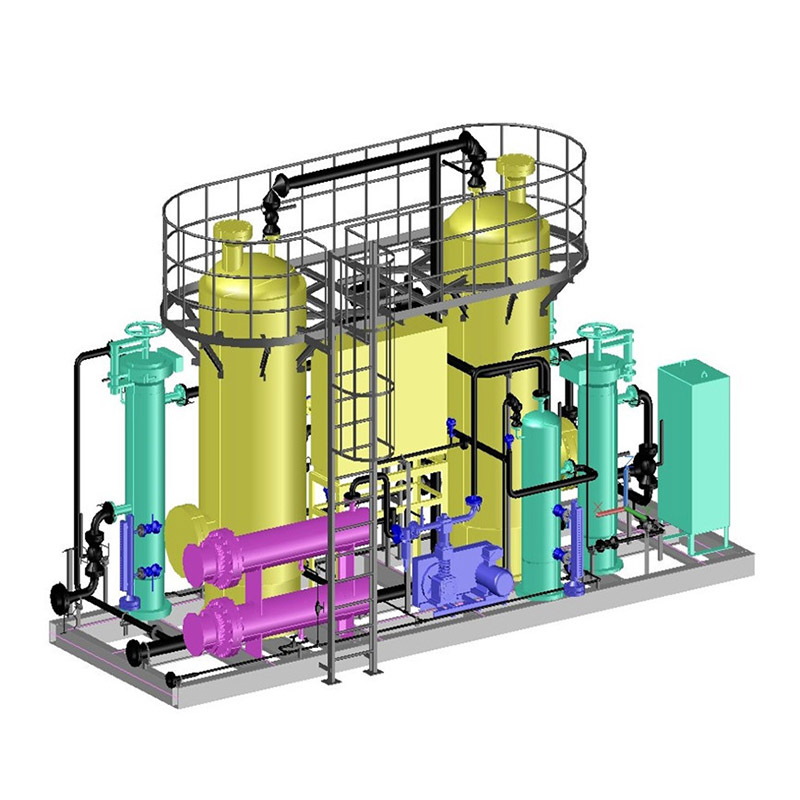

The process scheme mainly includes: feed gas pressure regulating and metering unit, natural gas purification unit and natural gas liquefaction unit, refrigerant storage system, refrigerant circulating compression system, LNG storage and loading unit.

The natural gas entering the station first passes through the pressure regulating and metering unit, which realizes the pressure regulation and metering of the incoming natural gas; The natural gas enters the natural gas purification unit, where the natural gas is subject to CO2 removal, H2S removal and dehydration treatment. MDEA process is recommended for decarbonization and H2S removal, molecular sieve dehydration process with three tower OR TEG dehydration process is recommended for dehydration; And It is recommended to use recovered and compressed BOG for regeneration gas;

Purified natural gas into the natural gas liquefaction unit, mixed refrigerant (MRC liquefaction process) is recommended for natural gas liquefaction; liquefied LNG is stored in storage tank, and atmospheric and low-temperature storage process is recommended for LNG storage. One atmospheric low-temperature storage tank is equipped with BG compressor, and BOG compressor is used to pressurize BOG before entering into molecular sieve dryer Regeneration, depending on cryogenic pump to achieve installation.

Technical parameters

1 Production capacity 90×104 m3/d

2 Tank capacity 10000 m3

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Professional Factory for 300ton/Day Gypsum Powder Processing Equipment Supplier, Our intention is “blazing new floor, Passing Value”, inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together!

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for Professional Factory for 300ton/Day Gypsum Powder Processing Equipment Supplier, Our intention is “blazing new floor, Passing Value”, inside the long term, we sincerely invite you to increase up with us and generate a vibrant long term together!

Professional Factory for China Gypsum Powder Production Line and Gypsum Powder Machine Manufacturer, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

-

Leading Manufacturer for China High Quality LNG...

-

Professional China Liquid Nitrogen Oxygen Argon...

-

Price Sheet for Quartz Sand Rotary Drying Equip...

-

2000 KVA Natural Gas Generating Set or gas genset

-

Short Lead Time for China 500kw 700kw 1MW 2MW 4...

-

2019 Latest Design 7000/7500/8000/8500 Watt Por...